-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In today’s fast-paced technological landscape, the demand for efficient and reliable electrical solutions has never been greater. PVC cable material stands out as a pivotal choice among engineers and manufacturers due to its remarkable properties and versatility in various applications. According to a report by the International Electrotechnical Commission, the global market for PVC cables is projected to reach USD 20 billion by 2025, driven by its extensive use in construction, telecommunications, and industrial settings. The exceptional insulation and durability of PVC, coupled with its resistance to moisture and chemicals, make it a preferred choice for modern electrical wiring. Furthermore, with the rising emphasis on sustainability, advancements in PVC recycling processes are enhancing its appeal as a green material, solidifying its position as an essential component in contemporary electrical systems. This article will delve into the numerous benefits of PVC cable material, illustrating why it remains a top choice for engineers and designers alike.

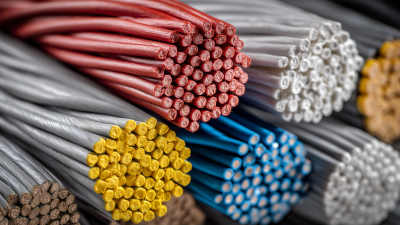

PVC (Polyvinyl Chloride) cable material is gaining prominence in modern electrical applications due to its unique properties that cater to diverse needs across various industries. Its flexibility and durability make it an ideal choice for both rigid and flexible cable types. This versatility allows PVC cables to be used not just in electrical and electronic applications but also extensively in construction, automotive, and healthcare sectors. The robust nature of PVC provides excellent insulation against moisture, chemicals, and temperature variations, ensuring safety and longevity in challenging environments.

PVC (Polyvinyl Chloride) cable material is gaining prominence in modern electrical applications due to its unique properties that cater to diverse needs across various industries. Its flexibility and durability make it an ideal choice for both rigid and flexible cable types. This versatility allows PVC cables to be used not just in electrical and electronic applications but also extensively in construction, automotive, and healthcare sectors. The robust nature of PVC provides excellent insulation against moisture, chemicals, and temperature variations, ensuring safety and longevity in challenging environments.

Moreover, the ongoing advancements in 3D printing technology are further driving the demand for PVC cables. As additive manufacturing techniques evolve, they increasingly enable the production of custom and complex cable designs that meet specific electrical demands. This growth in market applications reflects not only the adaptability of PVC in various settings but also highlights its role in supporting innovative solutions for modern infrastructure. Consequently, the anticipated rise in PVC market size from USD 706.3 billion in 2024 to USD 963.2 billion by 2031 underscores its critical importance in shaping the future of electrical applications.

Polyvinyl chloride (PVC) has established itself as a leading choice for cable insulation and jacketing in modern electrical applications, primarily due to its versatile properties that outperform many alternative materials. A report from the Institute of Electrical and Electronics Engineers (IEEE) indicates that PVC's excellent electrical insulation characteristics allow for a dielectric strength of around 20 kV/mm, making it highly effective for high-voltage applications. This ability to effectively insulate helps in minimizing the risk of electrical failures, which can lead to dangerous short circuits.

Moreover, PVC is known for its outstanding chemical resistance, making it suitable for environments where exposure to oils, chemicals, and other corrosive agents is common. The International Electrotechnical Commission (IEC) recommends PVC for various installations because its resilience can extend cable life and reduce maintenance costs. Compared to alternatives like rubber or thermoplastic elastomers, which may degrade faster under such conditions, PVC cables have been shown to last up to three times longer under similar exposure, underscoring their economic and operational advantages in the long run. Thus, for both durability and electrical performance, PVC remains a top choice in the cabling industry.

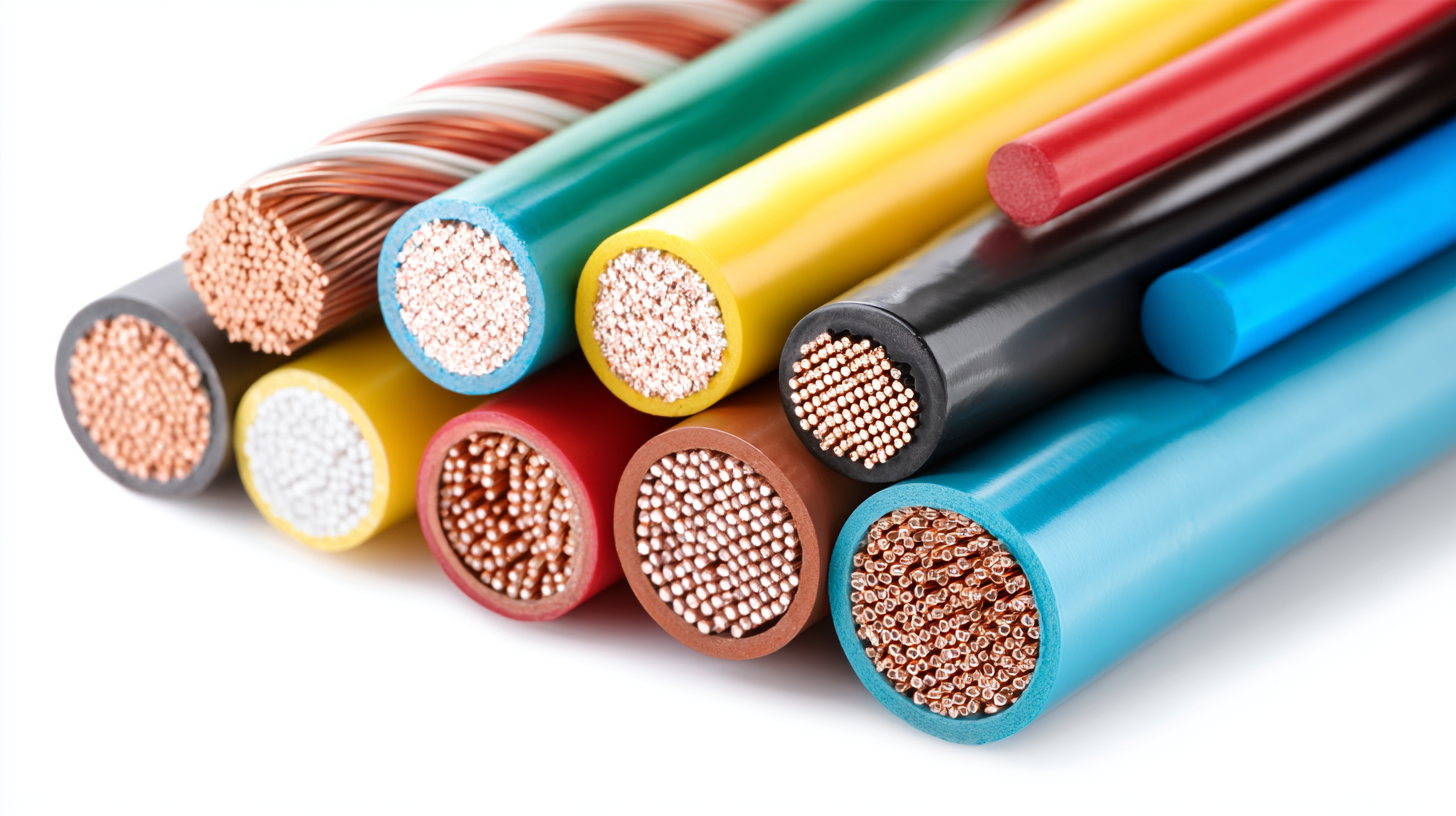

Polyvinyl chloride (PVC) cables have become increasingly popular in modern electrical applications due to their impressive durability and longevity. According to the Electrical Insulation Research Institute, PVC insulation has a lifespan of up to 30 years, significantly more than many other materials, making it an excellent choice for both residential and commercial installations. This longevity not only reduces replacement costs but also minimizes downtime, which is critical in industrial settings where every minute of disruption can lead to significant financial losses.

Furthermore, PVC’s resistance to moisture, chemicals, and UV radiation enhances its performance in harsh environments. A report from the International Electrotechnical Commission indicates that PVC cables can withstand temperatures ranging from -15°C to 70°C, thus maintaining their integrity under varying conditions. This adaptability makes PVC cables suitable for applications in diverse sectors, from construction to telecommunications. As businesses continue to prioritize reliable and cost-effective solutions, the impact of PVC cables on enhancing durability will undeniably play a critical role in the future of electrical engineering.

PVC cables have gained significant popularity in modern electrical applications, primarily due to their cost-effectiveness. When comparing materials for wiring solutions, PVC stands out as a budget-friendly option that does not compromise on performance. The production of PVC cables is generally less expensive, resulting in lower purchase costs for consumers. Additionally, their durability and resistance to environmental factors further contribute to their long-term value, minimizing the need for frequent replacements.

**Tips for Choosing PVC Cables:**

When selecting PVC cables for your projects, consider the specific requirements of your application. Look for cables that meet the necessary safety certifications to ensure reliability. It's also beneficial to assess the insulation thickness based on the environment in which the cables will be installed, as thicker insulation can enhance durability against moisture and temperature variations. Furthermore, always compare prices from multiple suppliers to ensure you are getting the best deal without sacrificing quality.

As we continue to embrace modern wiring solutions, understanding the total cost of ownership, including installation and maintenance, becomes crucial. Investing in quality PVC cables can lead to significant savings over time, making them an appealing choice for both residential and commercial electrical systems.

The growing emphasis on renewable energy and sustainable practices significantly impacts the electrical cabling market, particularly in the use of polyvinyl chloride (PVC) materials. While PVC has long been a popular choice for electrical applications due to its durability and cost-effectiveness, environmental considerations are now at the forefront of discussions regarding its use. The life cycle of PVC reveals certain environmental challenges, primarily relating to the production and disposal of this widely-used plastic.

To mitigate some of these concerns, innovations are emerging in the form of new PVC compounds that incorporate bio-based or bio-attributed additives, significantly reducing environmental impact. By transitioning towards these eco-friendlier alternatives, manufacturers not only enhance the sustainability of their products but also align with the broader shift towards renewable energy sources like solar and wind, which increasingly demand sustainable materials.

**Tips:** When selecting PVC cables, consider looking for products that include bio-based additives to help reduce environmental impact. Additionally, always check for certifications that signify adherence to eco-friendly practices. This approach not only supports a greener planet but can also enhance your project's overall sustainability goals.

| Benefit | Description | Environmental Considerations |

|---|---|---|

| Durability | PVC cables are resistant to abrasion, weather, and chemical exposure. | Recyclable materials can reduce landfill impact if disposed of properly. |

| Cost-Effectiveness | Lower production costs compared to other cable materials provide a budget-friendly option. | Environmental impact from production can vary; sourcing methods matter. |

| Flexibility | PVC cables offer excellent flexibility, making installation easier in tight spaces. | Flexible materials may be more challenging to recycle without proper facilities. |

| Insulation Properties | Good insulating properties prevent electrical leakage and increase safety. | Selection of non-toxic additives can enhance environmental safety. |

| Fire Resistance | Certain PVC cables are treated to resist fire, improving safety in electrical systems. | Use of halogen-free PVC can lower toxic emissions in case of fire. |