-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of modern technology, the significance of coaxial cable material cannot be overstated. Coaxial cables, which have been a staple in telecommunications and broadcasting for decades, rely heavily on the quality and composition of their materials to ensure effective data transmission and signal integrity. As technology continues to evolve, understanding how different materials affect performance, durability, and cost is crucial for both engineers and consumers alike.

This article aims to delve into the various types of coaxial cable materials available in the market, examining their unique properties and applications. By exploring the critical role each material plays, we can better appreciate how coaxial cables serve as the backbone of our interconnected world, supporting everything from internet connectivity to high-definition video broadcasting.

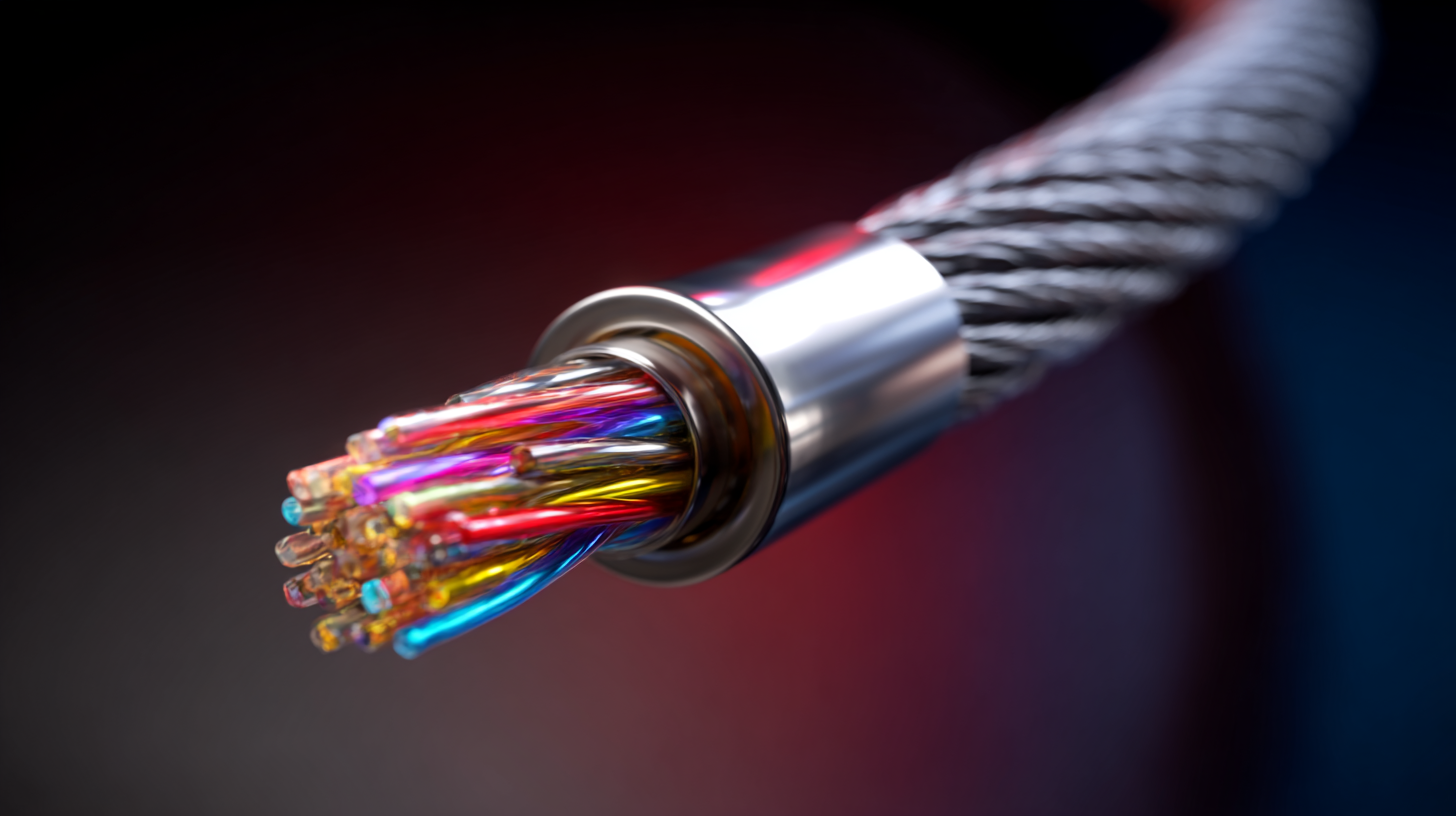

The material composition of coaxial cables plays a critical role in maintaining signal integrity and performance in modern technology. Coaxial cables are designed with an inner conductor, insulating dielectric, outer conductor, and protective jacket, each serving a vital purpose in reducing signal loss and interference. The choice of materials, such as copper for the inner conductor and variations of polyethylene for the insulator, directly affects the electrical characteristics of the cable, including attenuation and capacitance. High-quality materials can significantly improve the transmission of high-frequency signals, essential for applications like telecommunications and broadcasting.

Furthermore, the outer conductor's material and design contribute to the cable's shielding effectiveness against electromagnetic interference (EMI). A well-shielded coaxial cable minimizes noise and crosstalk, which is especially important in environments with multiple signal sources. As technology continues to advance, including the rise of 5G and high-speed data applications, the demand for coaxial cables made with superior materials increases. Understanding the interplay between coaxial cable materials and signal performance is crucial for engineers and technicians aiming to optimize systems for clarity and reliability in data transmission.

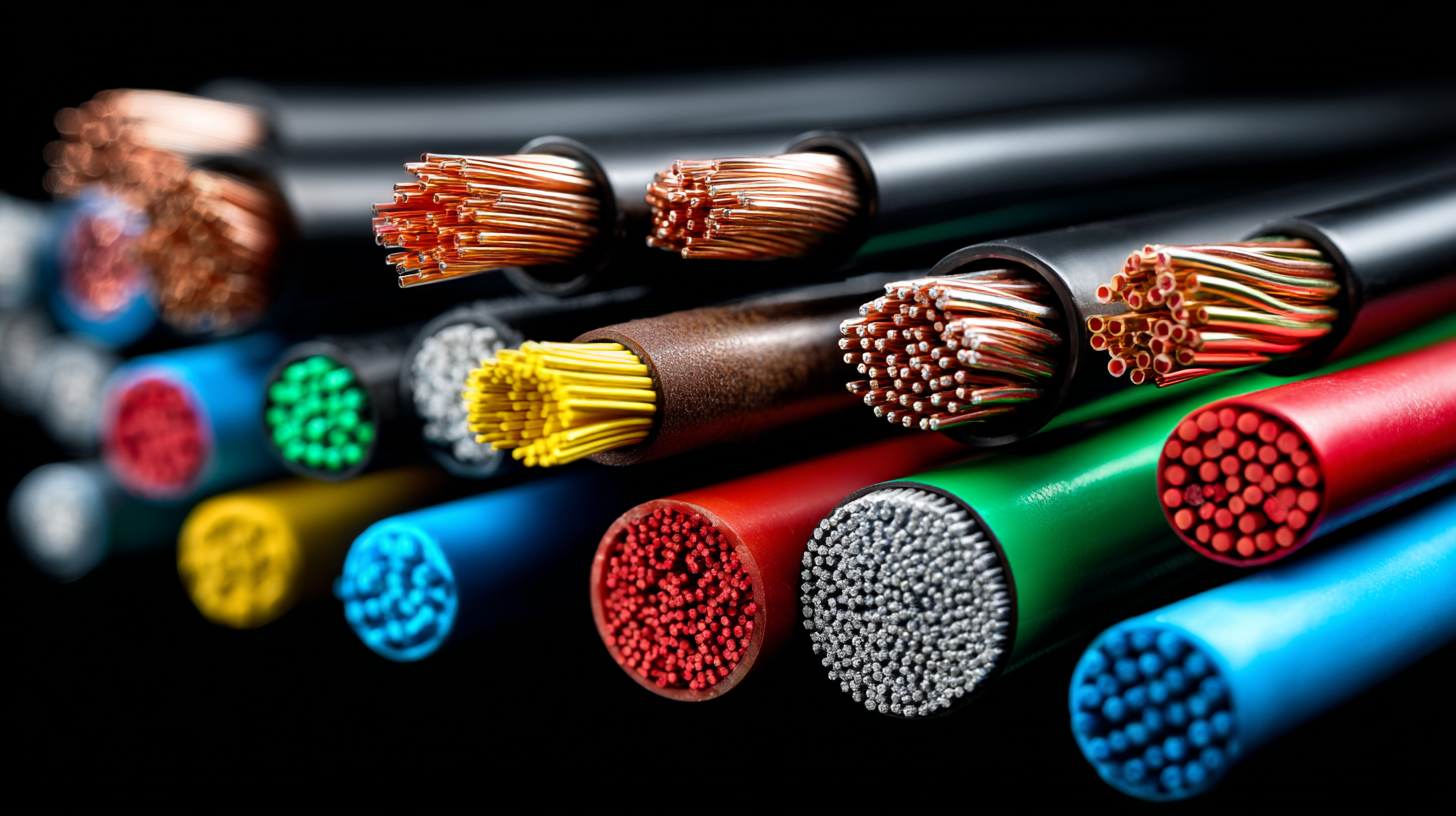

Coaxial cables, integral to modern telecommunications, derive their efficiency from the materials used in their construction. The most common materials employed include copper and aluminum for the conductor, which serve as the central core. Copper is often favored for its superior conductivity, allowing signals to travel faster and with less attenuation. However, aluminum is lighter and more cost-effective, making it a viable option in various applications where weight is a primary concern.

The insulating layer surrounding the conductor also plays a crucial role in the overall performance of coaxial cables. Generally, polyethylene or PVC (polyvinyl chloride) is used for insulation. Polyethylene provides lower dielectric loss, which is essential in high-frequency applications, while PVC offers better resistance to environmental factors and is more durable in rugged conditions. Additionally, the outer shield, typically made from a braided or foil material, protects against electromagnetic interference, ensuring that the signal remains clear and undistorted. These material choices are pivotal in determining the coaxial cable's efficiency, durability, and usability across a wide range of technologies.

| Material | Dielectric Type | Conductivity | Temperature Range | Common Applications |

|---|---|---|---|---|

| Copper | Air | Excellent | -40°C to 80°C | Television distribution, communications |

| Aluminum | Foam | Good | -50°C to 70°C | Satellite communications, radio frequency applications |

| Steel | PTFE | Moderate | -60°C to 85°C | Industrial applications, high-frequency use |

| Fiber Glass | Polyethylene | N/A | -40°C to 90°C | Telecom installations, broadcasting |

Choosing the right coaxial cable for your application is crucial to ensuring optimal performance and signal integrity. According to a report by the International Telecommunication Union (ITU), improper cable selection can lead to losses of up to 40% in signal strength, which could severely impact data transmission quality in high-frequency applications. When selecting a coaxial cable, consider key factors such as the material of the inner conductor, dielectric insulation, and outer jacket. Copper conductors, for example, are known for their superior conductivity compared to aluminum, making them ideal for high-frequency applications where signal clarity is paramount.

Additionally, the dielectric material affects the velocity factor and attenuation of the signal. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that using foamed polyethylene as a dielectric can reduce signal loss significantly—by almost 30%—compared to solid polyethylene. Furthermore, the outer jacket's material should be evaluated based on the installation environment; for instance, PVC is adequate for indoor applications, while UV-resistant materials are essential for outdoor installations. Thus, comprehensive research on material specifications is vital to select a coaxial cable that meets both performance requirements and environmental conditions.

The material choices in coaxial cables

significantly influence their durability and longevity, impacting their performance in a variety of modern technology applications.

According to a report by the International Electrotechnical Commission (IEC), the dielectric material used in coaxial cables, such as polyethylene or foam polyethylene, can affect the cable's resistance to environmental factors like temperature and moisture.

According to a report by the International Electrotechnical Commission (IEC), the dielectric material used in coaxial cables, such as polyethylene or foam polyethylene, can affect the cable's resistance to environmental factors like temperature and moisture.

For instance, cables with higher quality insulation materials exhibit an expected lifespan of over 30 years, while those using inferior materials may degrade within a decade.

Moreover, the outer conductor material, typically copper or aluminum, also plays a crucial role in the cable’s long-term performance.

A study conducted by the

Institute of Electrical and Electronics Engineers (IEEE)

highlighted that copper coaxial cables maintain lower attenuation levels and better signal integrity over longer distances compared to aluminum counterparts.

The report revealed that cables fabricated with copper for the outer conductor retained 90% of their original signal strength even after extensive exposure to harsh weather conditions, which reinforces the necessity of selecting appropriate materials.

These factors clearly demonstrate how material choices in coaxial cable design and construction can dictate their operational lifespan and reliability in modern technological applications.

Coaxial cables play a critical role in modern telecommunications, enabling efficient data transmission with minimal interference. The choice of materials used in coaxial cable construction significantly impacts performance. Traditionally, copper has been the go-to conductor due to its excellent conductivity. However, advancements in technology have introduced innovative materials that enhance signal integrity and durability. For instance, materials like aluminum provide a lighter alternative while still maintaining good performance standards. Additionally, the use of high-density polyethylene (HDPE) as an insulation layer offers improved resistance to environmental factors.

Tips: When selecting coaxial cables for specific applications, consider the environment they will be used in. If the cable will be exposed to extreme temperatures or moisture, look for materials that specifically offer enhanced protection. Moreover, always check the cable's specifications to ensure compatibility with your devices, as different materials can affect the cable's overall performance.

Moreover, advancements in coaxial cable technology also include the incorporation of advanced shielding materials. For example, using braided or foil shielding can significantly reduce electromagnetic interference, which is crucial in high-frequency applications. Understanding these innovative materials will empower users to make informed decisions about which coaxial cables best suit their needs and performance requirements.