-

Home

-

Products

-

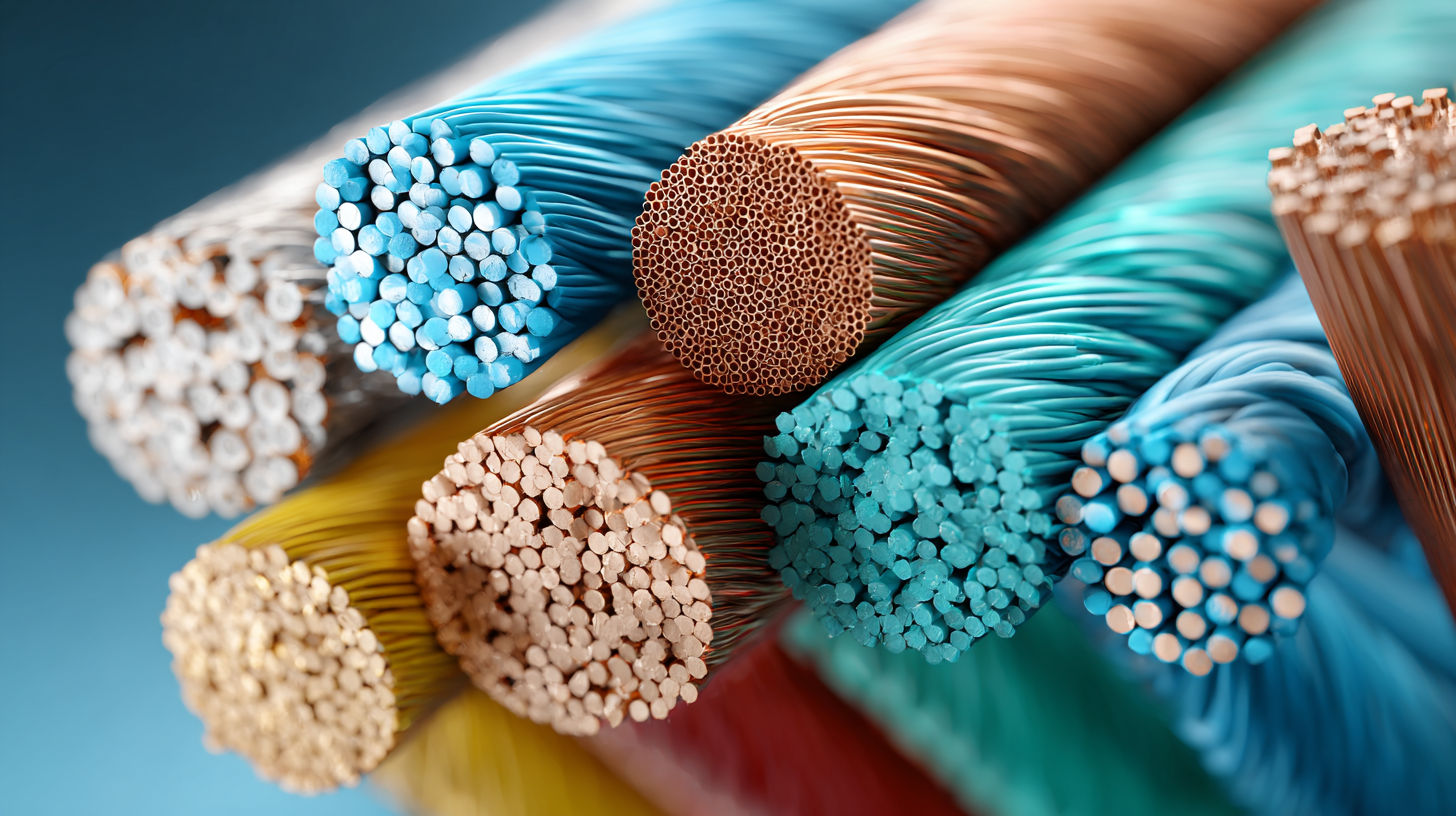

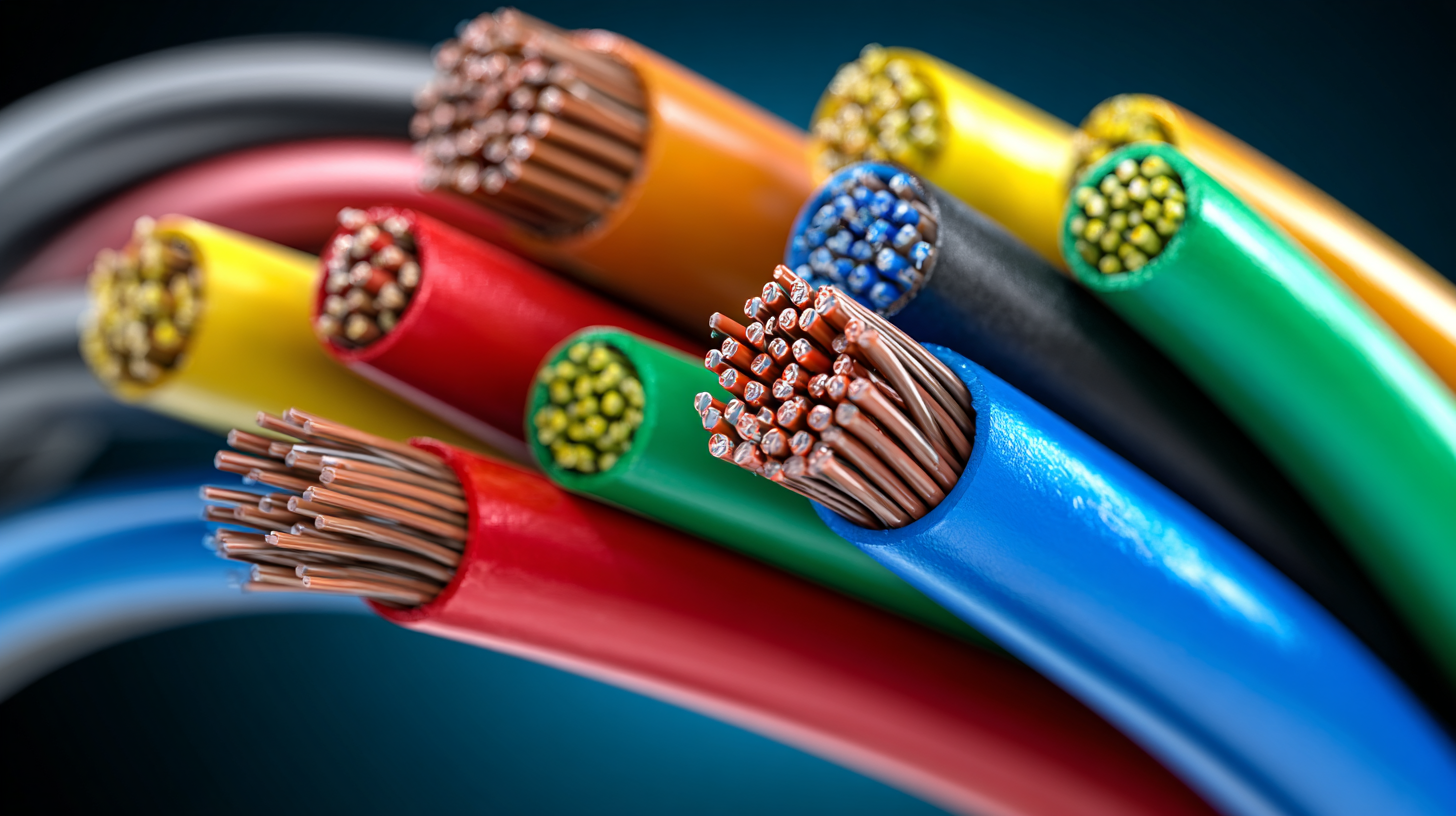

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of electrical engineering, the choice of materials is pivotal for enhancing efficiency and reliability. One of the critical components in this discourse is the PE cable material, known for its superior insulation properties and resistance to environmental stresses.

According to a report by the International Electrotechnical Commission (IEC), the global demand for polyethylene (PE) insulated cables is projected to increase by approximately 5% annually, driven by advancements in power transmission and renewable energy applications. This surge is attributed to the material's ability to withstand extreme temperatures and humidity, thereby ensuring a longer lifespan and reduced outage rates.

As professionals in the industry seek to optimize electrical systems, understanding the nuances of PE cable material will be essential for achieving not only compliance with standards but also operational excellence.

The growing emphasis on renewable energy sources such as solar, wind, and hydropower has led to an increased demand for innovative cable materials that enhance electrical performance. Key to this advancement is the utilization of cross-linked polyethylene (XLPE), which offers superior electrical insulation properties. As detailed in a report, the cable material market is projected to reach USD 20.1 billion by 2035, with significant contributions from the USA driven by high-performance cable needs in various sectors, including telecommunications and energy.

Moreover, the development of advanced insulation materials like Anthrone/XLPE is crucial for intelligent electric power transmission. These materials are designed to mitigate degradation risks commonly associated with local defects, thus ensuring improved reliability and efficiency in electrical systems. As manufacturers like those expanding XLPE production in Sweden recognize, the shift towards eco-friendly dielectric insulation materials not only supports sustainability goals but also addresses the critical need for enhanced fire safety and processing efficiency in modern electrical infrastructure.

When evaluating the thermal conductivity of PE cable materials, it is crucial to understand their impact on

efficiency and lifespan. Studies indicate that cables with superior thermal conductivity can efficiently dissipate

heat generated during operation. For instance, industry reports highlight that cables with high thermal conductivity can reduce operational losses by

up to 15%, demonstrating a significant improvement in overall performance.

Moreover, the lifespan of electrical cables is closely linked to their thermal management capabilities. According to the

International Electrotechnical Commission (IEC), improper heat dissipation can lead to accelerated aging and eventual failure,

reducing the expected lifespan of the cable by nearly 30%. By selecting materials that exhibit optimal thermal conductivity, manufacturers can enhance reliability, ultimately leading to

higher customer satisfaction and reduced maintenance costs. As electrical demands continue to rise, understanding the relationship between thermal conductivity and cable performance becomes essential for both manufacturers and end-users.

The dielectric properties of PE (polyethylene) cable materials play a crucial role in the reliability and efficiency of electrical systems. Enhanced dielectric strength is vital for ensuring the longevity and performance of cable insulation, particularly in high-voltage applications. Research indicates that advancements in materials such as cross-linked polyethylene (XLPE) have significantly improved the electrical insulation performance, making them a preferred choice for power transmission projects. This is especially important as the demand for reliable energy sources continues to grow alongside the transition towards renewable energy initiatives.

Furthermore, the aging phenomena in non-crosslinked polyolefin blends highlight the importance of dielectric properties. These materials, while offering a favorable alternative to traditional XLPE insulation, can experience electrical treeing and thermal aging, which compromise their performance over time. Therefore, continual research into the mechanical, physicochemical, and electrical properties of these materials is essential. The findings from recent studies not only enhance our understanding of material behavior under stress but also guide the development of innovative cable compounds designed to maintain their integrity and safety in varying environmental conditions.

When assessing the environmental factors affecting polyethylene (PE) cable performance, it's crucial to consider exposure to temperature fluctuations, humidity, UV radiation, and chemical exposure. According to recent industry reports, for instance, PE cables can maintain optimal performance in temperatures ranging from -40°C to 90°C. However, prolonged exposure to extreme conditions can lead to degradation, impacting both efficiency and reliability.

Tips: Regularly inspect cables in environments prone to temperature shifts or UV exposure. Consider utilizing protective coatings or sheaths to mitigate potential damage from sunlight and harsh chemicals.

Another critical factor is moisture. Industry studies indicate that water ingress can significantly reduce the electrical insulation properties of PE cables. Therefore, adopting moisture-resistant designs and ensuring proper installation techniques are essential for sustaining cable integrity.

Tips: Implementing effective drainage solutions and ensuring proper sealing during installation can help prevent moisture-related issues. Choosing cables with enhanced water-blocking features can further improve reliability in high-humidity scenarios.

The electrical cable industry is currently experiencing significant innovation, particularly in the realm of polyethylene (PE) cable technology. As the demand for high-performance and reliable power transmission grows, advancements in PE cable materials are crucial. These innovations focus on enhancing electrical efficiency and durability under various environmental conditions. The increasing adoption of renewable energy sources further emphasizes the need for cables that can effectively handle fluctuating energy demands, ensuring that energy loss is minimized and reliability is maintained.

Looking ahead, trends indicate a robust growth trajectory for the cable material market, with estimates suggesting it could reach USD 20.1 billion by 2035. This growth is driven by several factors, including advancements in manufacturing technologies and a heightened focus on sustainability. As industries embrace green technologies, the integration of innovative materials in cable production will become essential. Companies that invest in developing more efficient materials will not only meet regulatory requirements but also cater to the evolving demands of the marketplace, positioning themselves as leaders in an increasingly competitive landscape.

This chart illustrates key performance metrics of PE cable materials, highlighting their electrical efficiency, thermal stability, flexibility, and durability. Understanding these metrics is crucial for evaluating the reliability and efficiency of PE cable technology in modern applications.